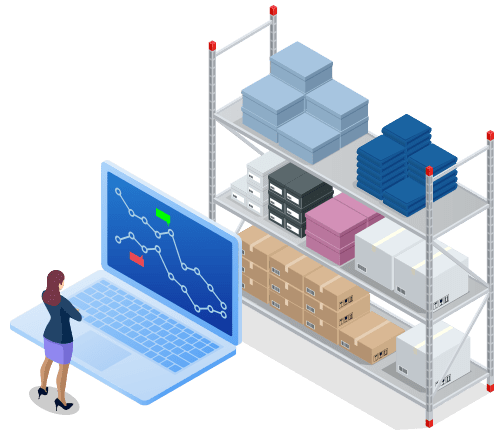

We build an Inventory & Distribution Management System that digitizes your entire flow: item setup, dealer requests, approvals, dispatch, receiving confirmations, on-site installation, and end-to-end lifecycle analytics. Warehouse admins add or import products and auto-generate unique QR codes to print and affix on items. Dealers log in to raise stock requests by product and quantity. Warehouse teams approve fully or partially, capture courier, AWB, and dispatch dates, and generate delivery notes. Dealers then confirm received quantities, noting any shortages. Field technicians scan product QR codes at installation to capture customer/site details. Management can then view a full chain-of-custody timeline and run powerful reports across stock, dealers, technicians, and regions.

Chat on WhatsApp FREE Consultation

Manual spreadsheets break at scale. Our system gives one source of truth across warehouses, dealers, and field teams. With QR codes on every item, you eliminate duplicate entries and misplacement while gaining scan-level traceability. Dealers raise requests in minutes, warehouse approvals are auditable, and dispatch events are logged with courier data. On receipt, dealers confirm actuals vs requests, recording shortages for instant resolution. Technicians scan the same QR at installation, adding customer/site metadata and warranty start. Dashboards surface bottlenecks - aging stock, top dealers, installation SLAs, and regional trends - so operations move faster with fewer errors and higher customer satisfaction.

Chat on WhatsApp FREE Consultation

From intake to install - every step digitized.

Unique QR per item ensures scan-based traceability from warehouse shelves to installed sites.

We create a great user experience making sure that your website design is optimized for usability and easy to use.

Digitize item setup, dealer requests, approvals, dispatch, confirmations, installations, and analytics.

Approve full/partial, record courier, AWB, date, quantities; generate delivery notes.

Dealer logs receipt, confirms actuals vs request, notes shortages for reconciliation.

Technician scans QR at site, captures customer details, geo, photos, and warranty start.

Item timelines from stock-in to installation with dealer/tech analytics and exports.

Answers on QR labels, dealer onboarding, courier data, shortages handling, installation proof, and analytics integrations for end-to-end visibility.

Yes. Generate and print QR labels from the system - single or bulk - using standard label printers.

Technicians scan QR and capture customer details, photos, geo-tag, date/time, and warranty activation.

Yes. We offer REST/GraphQL APIs to sync items, dealers, dispatches, invoices, and analytics dashboards.

We don't drop a generic inventory app into your complex network. We map your real flows - multiple warehouses, dealer hierarchies, partial approvals, courier integrations, and field installations - into configurable modules. Our system supports barcode/QR, role-based access, scan logs, attachments, geo-tagging, and e-sign proofs. With REST/GraphQL APIs, you can connect ERPs, CRMs, or BI tools. Performance is tuned for large catalogs and high scan volumes, while audit trails keep compliance simple and investigations fast.

Chat on WhatsApp FREE Consultation

API-first architecture, clean UX, and robust reports you'll actually use.

See an item's journey across stock-in, dealer, dispatch, and install - down to the scan event.

Simple, mobile-first screens for dealers and techs reduce training and data errors.

Aging stock, shortages, SLA breaches, top dealers/techs, and regional heatmaps in one place.

Stop juggling spreadsheets and calls. Give your warehouse, dealers, and technicians a single system that tracks every item with QR precision. Launch faster approvals, cleaner dispatches, accurate receipts, and verified installations - backed by reports that drive decisions. Talk to us for a live demo tailored to your process.

Chat on WhatsApp FREE Consultation

We are a team of hard-core nerds and we are bringing more of you that marketing advantage with top rate ecommerce websites.